QHSE

HSE Policy

Harmans Floreat Limited is committed to being recognized as a leader in Health, Safety, Environment, and Quality (HSEQ) management. The company’s goal is to achieve “zero injuries, zero accidents, zero illnesses or harm to the environment”.

Key commitments include:

- Protecting personnel, the environment, and equipment.

- Establishing and maintaining a safe and healthy work environment.

- Complying with regulatory laws, rules, client requirements, and industry standards.

- Eliminating hazards and reducing risks through systematic risk assessments.

The company aims for:

- Meeting or exceeding customer requirements and expectations.

- Zero injuries.

- Zero environmental incidents.

- Zero defects.

- On-time delivery.

- Continuous improvement.

These goals are achieved by operating in compliance with their HSEQ Management and Safety Management Systems, and through consultation and participation of employees. All employees are expected to adhere to these laws, regulations, and ethical standards, with management responsible for ensuring compliance.

HSE Manual Highlights

Harmans Floreat’s Health Safety, and Environment (HSE) Manual is the governing document outlining requirements applicable to Harmansfloreat and its subsidiary companies. All employees are required to read and be familiar with its content.

Key Safety Requirements:

- Permit to Work System (PTW): A written procedure is in place to protect individuals working in high-risk areas or activities, outlining steps before, during, and after work completion. This system helps coordinate risk and prevent hazards.

- Personal Protective Equipment (PPE): A minimum set of PPE, including safety boots, high-visibility clothing, gloves, helmets, and eye protection, is mandatory at all worksites. Additional PPE may be required based on risk assessments and local regulations.

- Work at Height: Operations involving work at height must be properly planned, supervised, and carried out by competent personnel. These activities require a Risk Assessment (RA) or Task Risk Assessment (TRA/SJA) and a Permit to Work (PTW). Rescue plans and equipment must be available.

- Dropped Object Prevention: Measures are in place to prevent falling objects (tools, equipment, loose items) that could cause injury, material damage, or environmental impact. This includes establishing drop zones with no-access barriers, securing tools with lanyards, and thorough inspections after work.

- Confined Space Work: Work in confined spaces requires a PTW, a Task Risk Assessment (TRA/SJA), and a rescue plan. Air quality testing is critical before entry to ensure normal oxygen levels and absence of toxic gases.

- Lifting Operations: Procedures address risks associated with lifting, such as dropped loads or crushing. Approved lift plans and PTWs are required for specific operations, and all personnel involved must be qualified and competent.

- Chemical Handling: Policies are in place for the safe handling, storage, and disposal of chemical products, emphasizing the use of less hazardous alternatives and mandatory PPE as per Safety Data Sheets (SDS).

- Traffic Safety: Driving or being a passenger in a vehicle is recognized as a high work-related safety concern. Requirements include pre-use vehicle checks, safe driving practices (obeying speed limits, wearing seatbelts, avoiding distractions), and immediate reporting of damages or incidents.

- Emergency Response: The manual outlines procedures for emergency response, including fire fighting, first aid, and medical emergency responses.

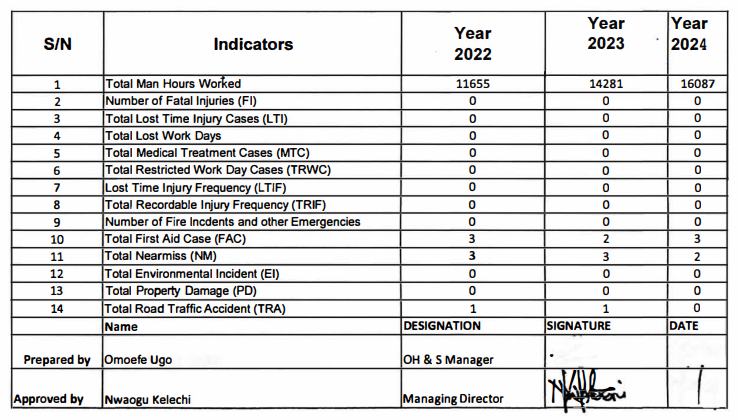

Health, Safety & Environment Statistics (2022-2024)

Harmans Floreat Limited maintains a strong safety record with the following cumulative OH&S (Occupational Health & Safety) statistics for the past three years:

Harmans Floreat

Harmans Floreat Limited, established in 2016, specializes in Oil & Gas and Telecommunications while expanding into renewable energy, offering comprehensive solutions for supply and purchase of petroleum products, telecommunications, and diesel management.

Quick Links

- Services

- Policies

- Projects

- About Us

- Staff Webmail

- Sitemap

Socials and Contact

- 6, Onyeke Amadi Crescent, Odani Green City, Elelenwo, Port Harcourt, Rivers State

- management@harmansfloreat.com

- 08152733698

© 2025 Harmans Floreat Limited